by Dr. Yoon Chang

by Dr. Yoon Chang

I will get to my particular reasons for working on a small modular IFR at the end, but first let me review some underlying considerations.

1. Technically small reactors are very sound.

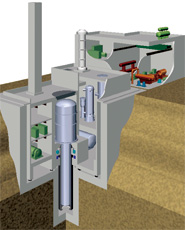

If we can build 1000 Mwe plants, then 10 Mwe or 100 Mwe plants are that much easier. So I find a small reactor design, such as 4S (Super-Safe, Small & Simple)is technically sound and well designed. There is no magic about a long-life core. If you start with a derated core, say 6 times more fuel compared to convential 5 year core, then you have 30 year life with the same burnup level. Neutron damage on cladding will be higher, but since the netron flux level is lower at a derated core, the neutron dose increase is less than a factor of two, which is doable. However, this requires a good neutron economy, which metal fueled fast reactor provides. [By the way, the TWR is based on the same principle, except the moving part, which complicates the cooling arrangements.

2. However, small reactors do not fare as well when it comes to economics.

My own experience will illuistrate this point amply. About 20 years ago, I had a chance to work together with a potential reactor vendor in designing a 10 Mwe terrestrial reactor for a client (I believe it was Air Force) with potentially large number of orders. A detailed design was developed with a preliminary cost estimate. The proposal was well received by the client, who then issued a

RFP for a fixed price contract. When the vendor worked with component suppliers to come up with a fixed price, it turned out many times the original estimate. Ovbiously the client's interest quickly evaporated. Small reactors cannot compete with the economies of scale.

3. Can factory manufacturing of multiple units overcome the economies of scale?

All nuclear plant components are factory manufactured -- small or large. Even large pressure vessels are now forged in few pieces. Furthermore, modular construction approch allows more and more factory assembling -- small or large. If manufacturing 100 small components repeatedly can lower the unit cost, so would manufacturing 10 large components repeatedly. So I do not buy a faster learning curve arguments.

4. Large reactor projects are too complex causing delays?

This was the perception in the late 80s, prompting Westinghouse to develop AP-600. AP-600 was the first and earliest design certified by NRC, but no takers. Hence AP-1000 was developed, but the first customer, China demanded uprate to 1400 Mwe. All 26 reactors that utilities have applied for NRC licenses are large units in the 1400-1800 Mwe. Large units have been built without delays in Japan and Korea, and now in China.

5. Small grid system demands small reactors or incremental expansion?

In the U.S. essentially all grids are tied to regional systems and interconnected. That's why all present reactor oders as indicated above are large units, which represents a small fraction of the national grid of more than 500 Gwe. Small utilities can buy into portions of a large unit. For example, a small utility serving San Antonio bought 20% equity position (and electricity) of the NRG's South Texas project. In overseas market, small grid countries like Vietnam and Indonesia indicated interests in nuclear but they are looking at 1000 Mwe class for economic reasons.

6. How about remote sites or dedicated power source for industrial process heat application?

There could be a niche market, but still the bottom line will be the generation cost. Small reactors cannot compete with gas turbines or

other fossil plants that can be sized to the demand.

In spite of my prejudice, I believe there might be a case for small modular reactors of the PRISM size, namely 300-600 Mwe. The economic penalty is only nominal but offers other intangible advantages. Below that level, if we go down to 10-50 Mwe range, the economic penalty will be too high to be practical.

Why then did I work on a 50 MWe IFR design? The motive was simply to initiate a project to maintain the technology base and train next generation enginners required for the future. For this purpose, almost any reactor size will do but a small reactor project cost will be more affordable.