Some Good News About Carbon, For a Change

By Tom Blees, President of SCGI

When it comes to dealing with CO2, public discussion and policy initiatives generally revolve around auto and power plant emissions, what Bill Gates referred to as “the low hanging fruit” in his February 15 interview with Anderson Cooper on 60 Minutes. He continued “…that’s getting almost all the money, not the hard part, which is the industrial piece, including the steel and cement…those pieces we’ve hardly started to work on.”

So let’s work on that here.

CO2 emissions from the steel and cement industries account for about 16% of global carbon dioxide emissions. The sheer scale of the cement industry is hard for the human mind to grasp. Jonathan Watts, a writer for The Guardian, made a valiant attempt:

In the time it takes you to read this sentence, the global building industry will have poured more than 19,000 bathtubs of concrete... After water, concrete is the most widely used substance on Earth. If the cement industry were a country, it would be the third-largest carbon dioxide emitter in the world…”1

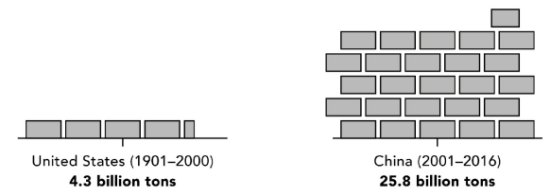

Bill Gates's new book, How to Avoid a Climate Disaster, illustrates the immensity of the steadily growing cement industry with this illustration:

China makes a lot of cement. The country has already produced more in the 21st century than the United States did in the entire/ 20th century. (U.S. Geological Survey) China makes a lot of cement. The country has already produced more in the 21st century than the United States did in the entire/ 20th century. (U.S. Geological Survey)

As developing countries continue to advance and more cities are built, this is not a problem that is going to go away. So if we’re serious about coping with the Gordian knot of climate change, we have to figure out a way to get the CO2 emissions of the cement industry—and the steel industry—out of the equation. Is that even possible?

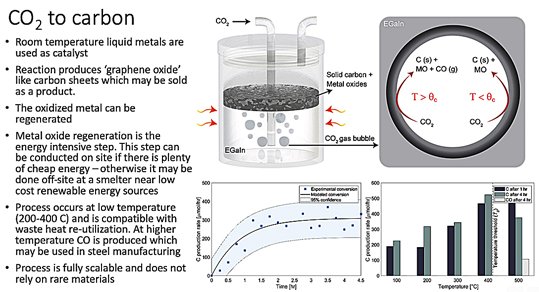

A team of researchers in Australia may have a solution to this thorny dilemma. They have devised a method of producing pure solid carbon from carbon dioxide using room-temperature liquid metals as a catalyst. Though only done at lab scale so far, the process should be fully scalable and doesn’t rely on any rare materials. The implications of this process being deployed into widespread use are staggering, especially in terms of eliminating emissions from the cement and steel industries.

Cement manufacturing has two different sources of CO2 emissions. The process is quite straightforward and has been used since the days of ancient Rome though, interestingly, the process was forgotten for centuries during the Dark Ages and had to be rediscovered later, even though Roman concrete structures like the still-impressive Pantheon were there for all to see. In most cases of cement manufacture, limestone is heated in a kiln to produce calcium oxide and carbon dioxide. The former is the main ingredient in cement, the latter is discharged into the atmosphere. The kilns are most often fired with natural gas, which also produces CO2 that adds to the emissions.

It is entirely possible to fire the kilns with electricity, which is sometimes done, but the cost differential between electricity and natural gas usually results in gas being used. The carbon dioxide emission from both the gas-fired kilns and the chemical process of producing the cement is quite clean and can be captured. Using the aforementioned process to extract pure carbon from those emissions, the carbon can then be added to the cement in place of the more normally used sand. Surprise! Concrete made using carbon in place of sand is about 60% stronger than normal concrete. So you end up with not only carbon-neutral concrete but a far better product to boot.

As for the carbon used in steel production, that too has several pathways. Though blast furnaces can be fired using plasma torches (so-called electric arc furnaces), about 70% of steel is made in blast furnaces fired by coal. Carbon monoxide is used as a reducing agent to remove the oxygen from iron oxide, in the process creating—you guessed it—carbon dioxide. Carbon is also incorporated into the steel itself as an essential ingredient, in differing amounts depending upon the type of steel that’s being made.

So can steel be made without using coal? Most definitely yes. The same process that the Aussie team is developing will produce carbon monoxide at higher temperatures, which can be used as the reducing agent in the steel-making process. The CO2 that results can be captured and made into carbon that is incorporated into the steel or recycled into more carbon monoxide.

Okay, wait a minute. This sounds like a perpetual motion machine. What’s the catch?

Energy. A lot of it. There’s no free lunch.

Imagine that you’re burning coal that’s 78% carbon (different types of coal range from lignite at about 60% to anthracite at over 80%). Complete combustion of one short ton (2,000 pounds) of that coal will generate about 5,720 pounds (2.86 short tons) of CO2. Recovering the carbon from that CO2 is like turning it back into coal, more or less, though the resulting product would be pure carbon without the other ingredients in normal coal (oxygen, hydrogen, sulfur, etc.). That’s going to take a lot of energy.

So once again, it comes down to the question of energy supply and cost. It always does. How much energy does desalination require? How about the energy for electrolysis to get hydrogen from water to make synthetic fuels? Energy choices and their economic and environmental impacts are the key factors in powering modern civilizations. There’s no escaping it.

Here at SCGI, we’ve tried to minimize the nuclear vs renewables argument, though it’s impossible to avoid it completely and I’m not going to debate it here. So for purposes of this discussion, I’ll just break it down like this: We can agree that we want to phase out fossil fuels because even if we captured and sequestered 100% of emissions from coal and natural gas, there are still huge amounts of emissions from the mining and drilling and transport of these fuels. So we want to run civilization with clean (i.e. non-emitting) energy sources. At the moment only a few of these have shown widespread scalability: hydroelectric power, wind, solar, and nuclear. But hydropower is limited and subject to wide variability, particularly in times of drought. Wind and solar sometimes are simply not available at all, sometimes for days or even weeks, over large areas. So aside from sheer fantasists (and there are, alas, many), reality-based people would agree that some sort of “backup” power is needed for those times—even if they’re rare (they’re not, but…)—when wind and solar fail. So that leaves nuclear power to be built to provide that “backup”.

We’re not going to debate the cost here, a favorite target of anti-nuclear arguers. I will mention, however, that the Electric Power Research Institute (EPRI)—the premier think tank and R&D hub of the electricity industry—delved into the seemingly unbelievable claim that floating power plants using molten salt reactors can be built for about a dollar per watt. Their considered finding, soon to be published, is that they can be built for about eighty cents to a dollar per watt. So even if they’re so far off (and they are a very reputable organization) that it costs three dollars a watt, that would still work. We could still build sufficient nuclear power plants economically to provide “backup” power to provide for peak electricity demand when wind and solar (and storage) fail. And they can be built quickly using shipyard technology. For more on this, see this article and the links it contains.

Okay, so imagine that we’ve already built humanity’s energy supply on clean energy only. We now have sufficient nuclear power plants to meet peak electricity demand around the world. But peak demand is about two to three times average demand, depending on the industrial/residential profile of the area being supplied. Nuclear fuel costs are trivial, nuclear fuel supplies are unlimited (you can get it from seawater, in addition to the usual sources), and nuclear power plants are just fine running at full power, 24/7. So that means you can supply all the power—just from nuclear plants—that your electricity grid demands. You’ll have that much—or even twice that much—excess energy to use for whatever other purposes you might choose: desalination, hydrogen production, ammonia production, synthetic fuel production, or (to the point of this article) deriving carbon from carbon dioxide.

Because of the variability of electricity demand and the many beneficial uses to which excess nuclear energy can be applied, it’s really a mistake to look at a nuclear power plant’s rated output and think of it only in terms of the electricity it can produce. Yet that electricity production is, up to now, the only way that nuclear power is paid for. A fully capitalized nuclear power plant in the USA can usually produce power for a bit under two cents per kilowatt-hour. Because of ridiculous energy policies, even that tiny cost still makes nuclear plants, at some times, allegedly not profitable, but that’s a whole different discussion. Suffice it to say that if a nuclear power plant can earn sufficient income to pay for itself selling electricity, then all the excess energy it produces (as described above) is pretty close to free.

But of course, hydrogen and ammonia and fresh water and pure carbon are all valuable commodities, so using nuclear power plants’ excess energy for these purposes can definitely make them profitable, while at the same time producing highly beneficial products.

Presently, nuclear power provides about 10% of the world’s electricity, but only about 4% of the world’s total energy demand. We can definitely scale it up, and quickly (again, see the aforementioned article for more on this), to produce all the electricity we need and start taking a big bite out of that total energy demand.

Right now we don’t know just how much energy it will take to run that carbon process backward, to make carbon from CO2. The researchers are now in the process of raising the money to build a larger system in their lab to produce kilos of carbon, at which point they’ll be able to analyze the data and determine the energy cost to operate the system on a large-scale global deployment.

In discussing this with the leader of the Aussie research team, Torben Daeneke, the idea of glutting the industrial carbon market was raised. Indeed, that could happen. But what if we actually provide all the carbon that industries (steel, concrete, rubber tires, etc.) can use to run clean and green, and we still have a lot more leftover? Well, it turns out that carbon is also great for the soil, so any excess can be directed to the agriculture industry to great effect.

A year into the pandemic, all of us can use some good news. This is good news. Enjoy!

1 Concrete: The Most Destructive Material on Earth, from The Guardian, Feb 25, 2019, https://www.theguardian.com/cities/2019/feb/25/concrete-the-most-destructive-material-on-earth

|

![]()

![]()

![]() The Science Council for Global Initiatives is a nonprofit 501(c)(3) charitable organization. All contributions are tax-deductible.

The Science Council for Global Initiatives is a nonprofit 501(c)(3) charitable organization. All contributions are tax-deductible.